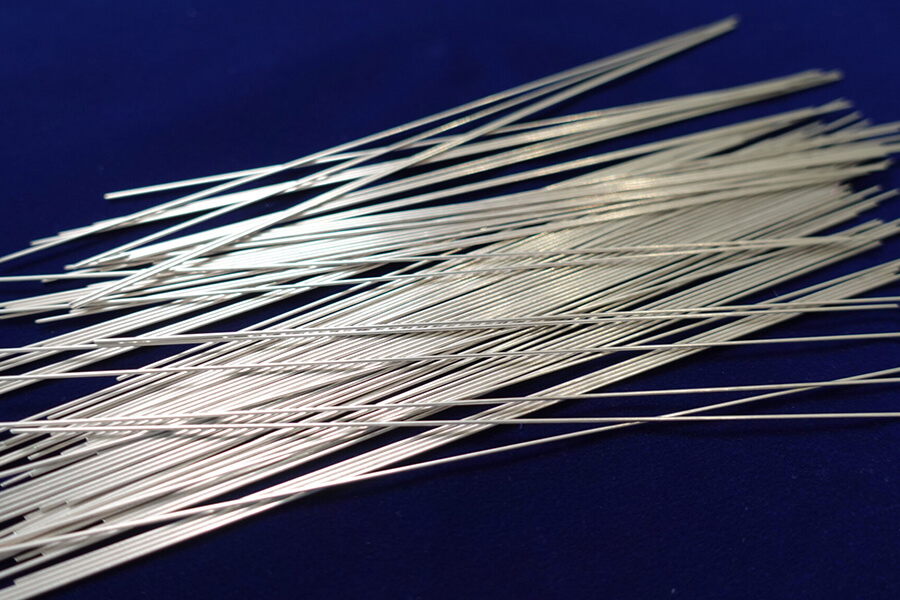

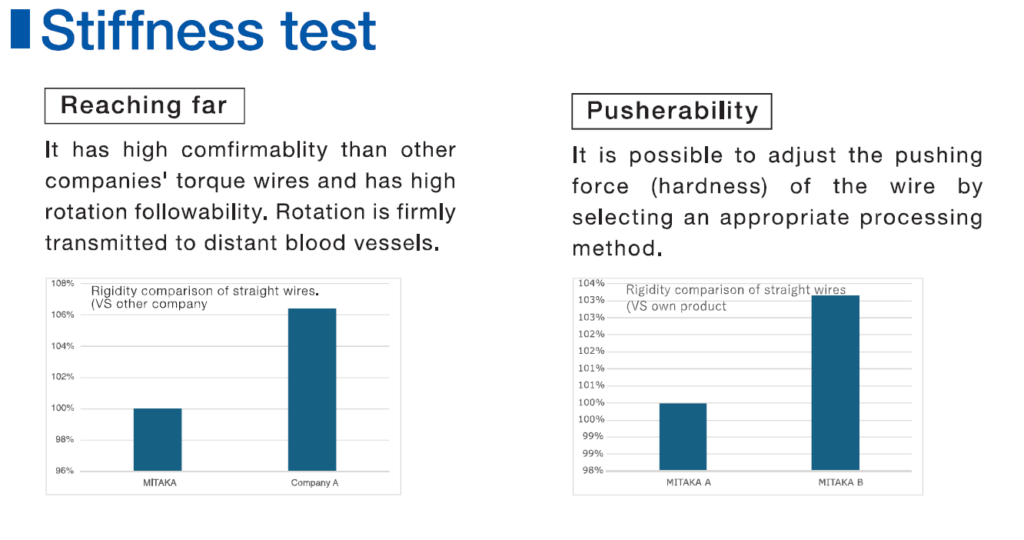

〇Reaching Far with Strength

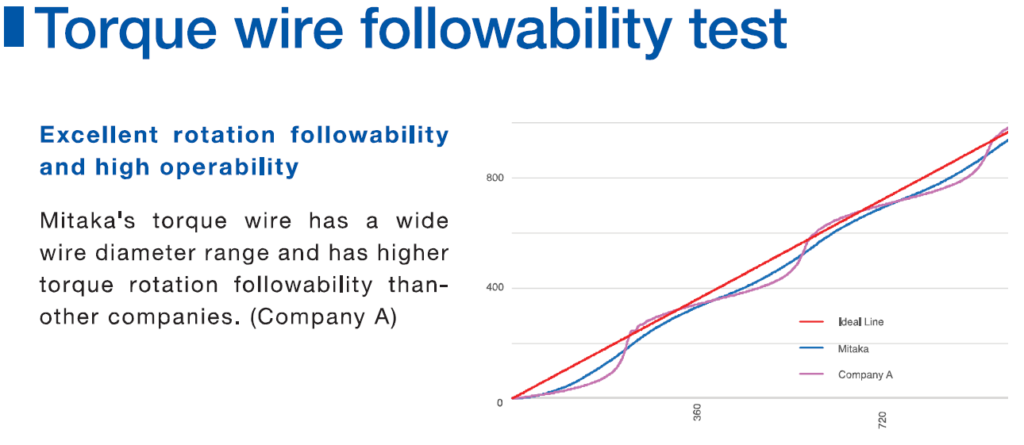

〇Superior rotational tracking and torque transmission

〇Thin and flexible enough to reach capillaries

Characteristics

- High-straightness

- Excellent torque tracking

- Stable mass production

Main usage

- Medical core guide wire

- Mandrel for resin tube forming

- Stylets for injection needles

Compatible specs

Materials

Stainless steel, tungsten, titanium, beryllium, other superalloys

Shape

Round wire

Wire diameter

The wire diameter is φ0.02 to φ0.90

Overall length

20mm to 5,500mm

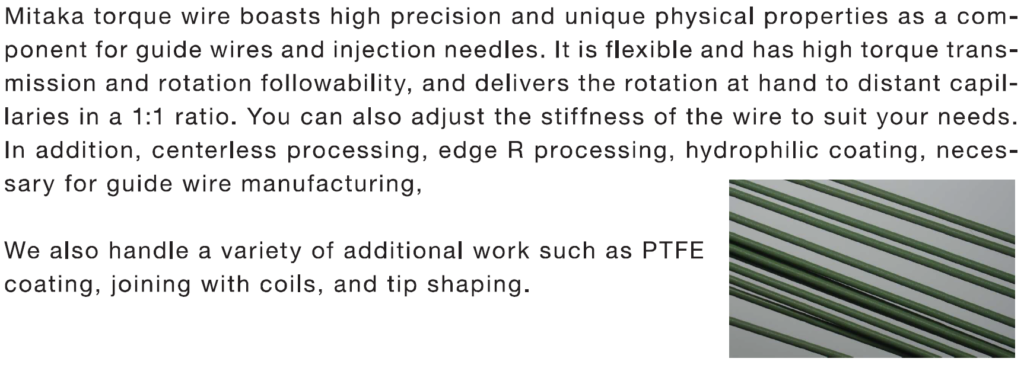

Processing

Centerless processing, edge rounding, PTFE coating, taper processing, forming, etc.