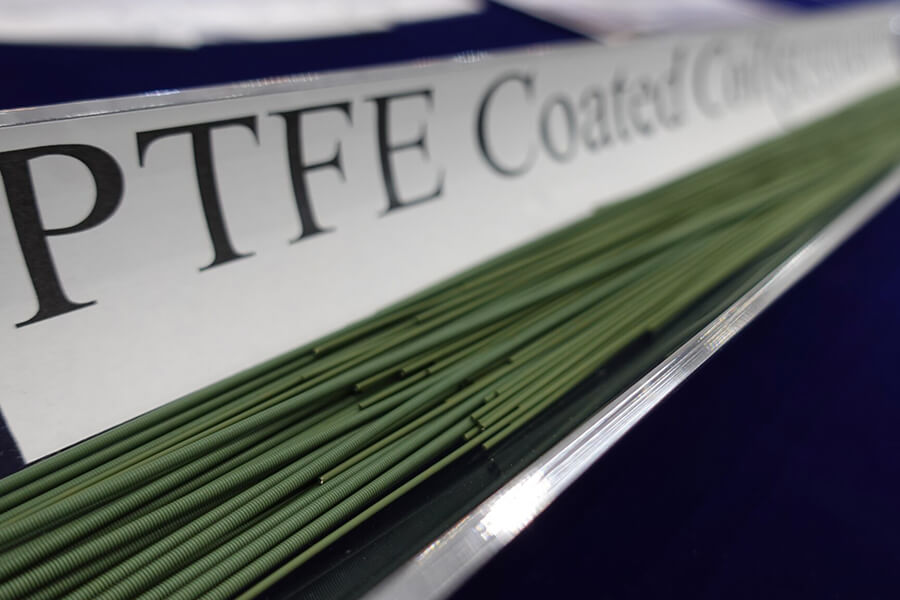

Characteristics of PTFE coating

Fluor resin has physical properties such as non-adhesiveness, heat/cold resistance, slidability, electrical properties, wear resistance, chemical resistance and non-wetting resistance.

Most things will not stick to the coating film, and even if it does stick, it can be easily removed.

It can be used in a wide range from 260 degrees to -240 degrees and has excellent nonflammability.

Varies with load and sliding, but very low coefficient of friction

It has the best electrical properties of all resins, such as insulation, low dielectric loss, and arc resistance.

Strong film strength is added by combining the properties of Teflon with organic binder resins and ceramics. This makes it resistant to wear under heavy loads.

It is hardly attacked by both acid and alkalis.

In addition to repelling oil and water, it does not get wet with most solvents. It’s stain resistant and easy to clean.

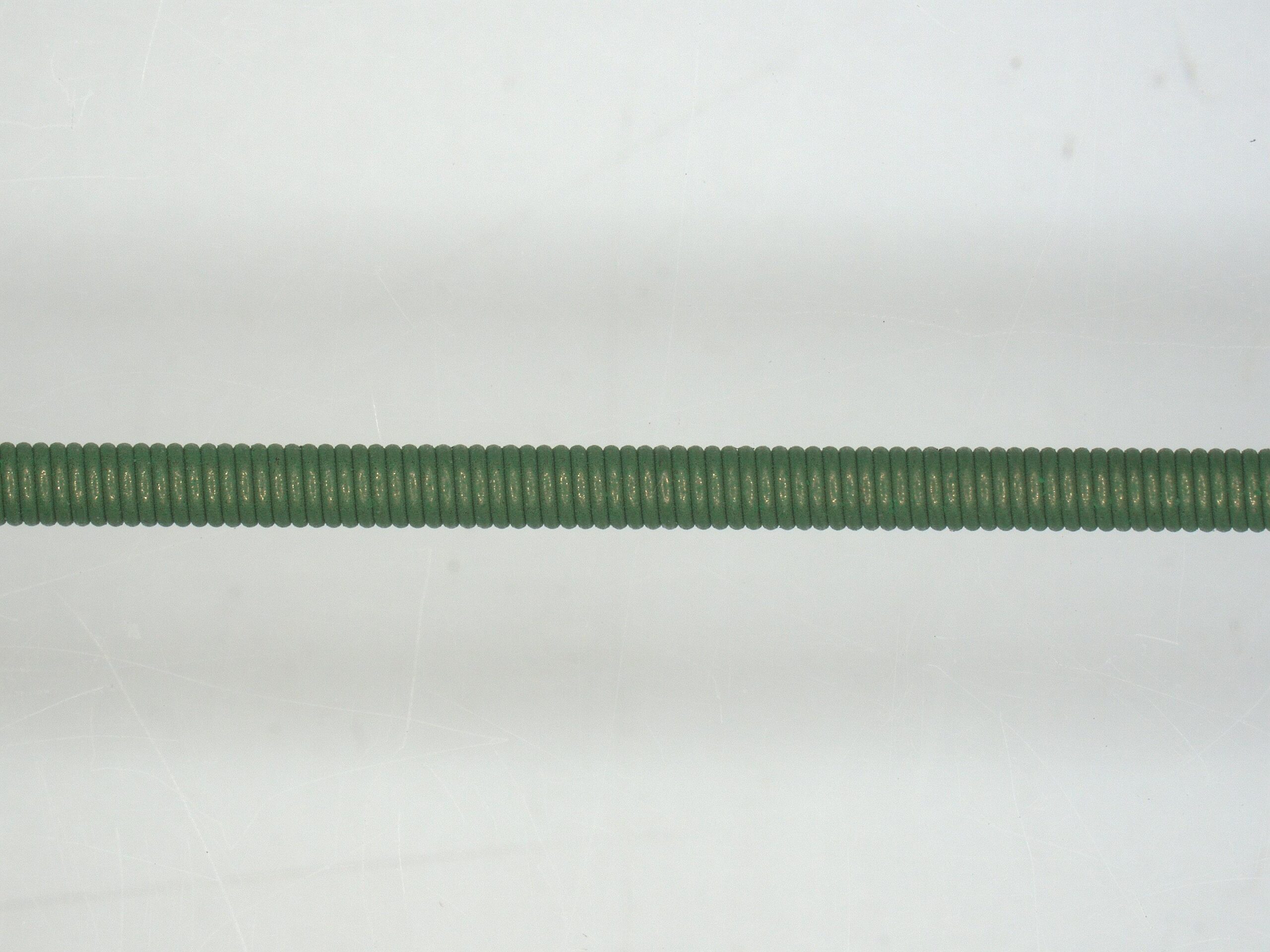

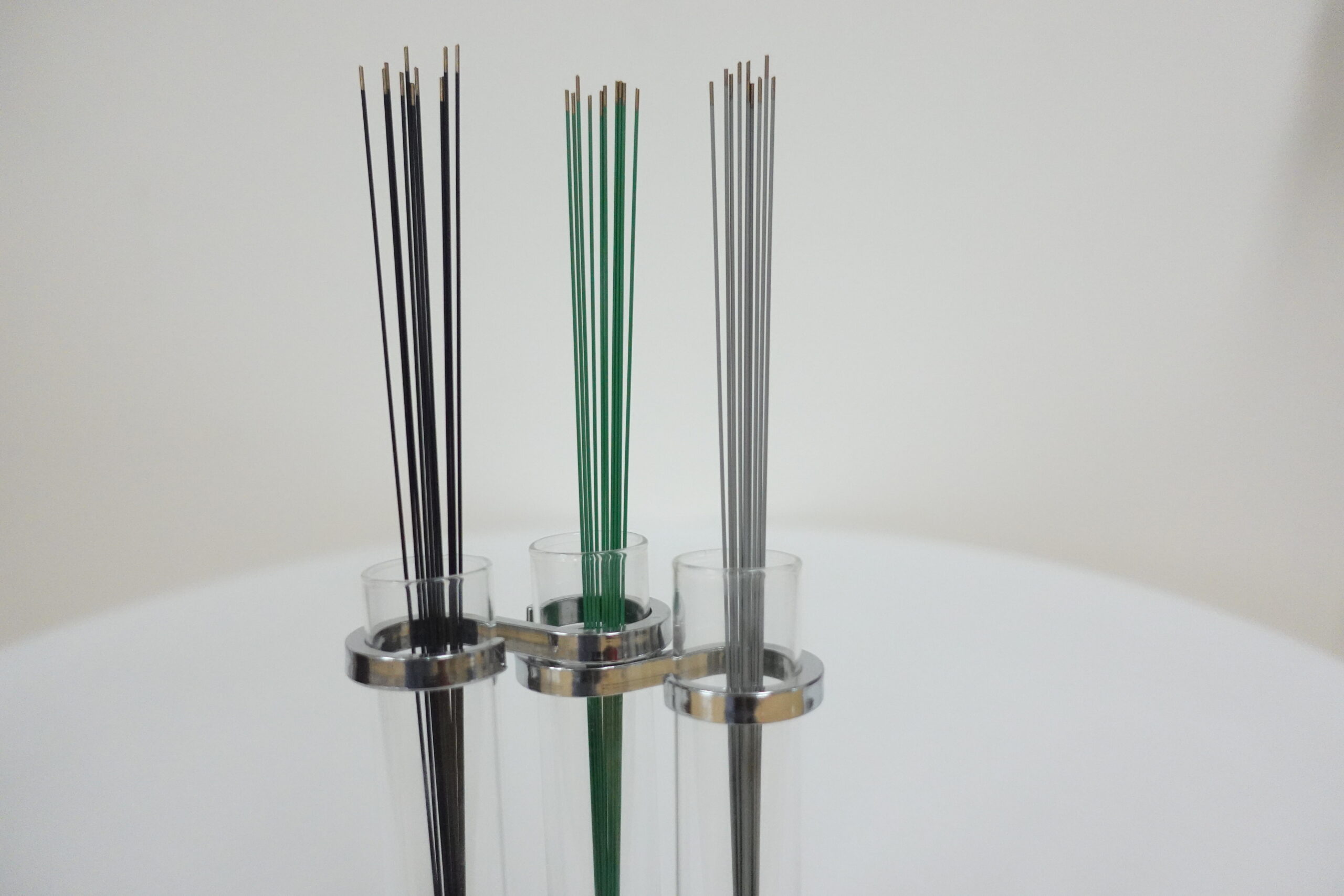

Compatible specs

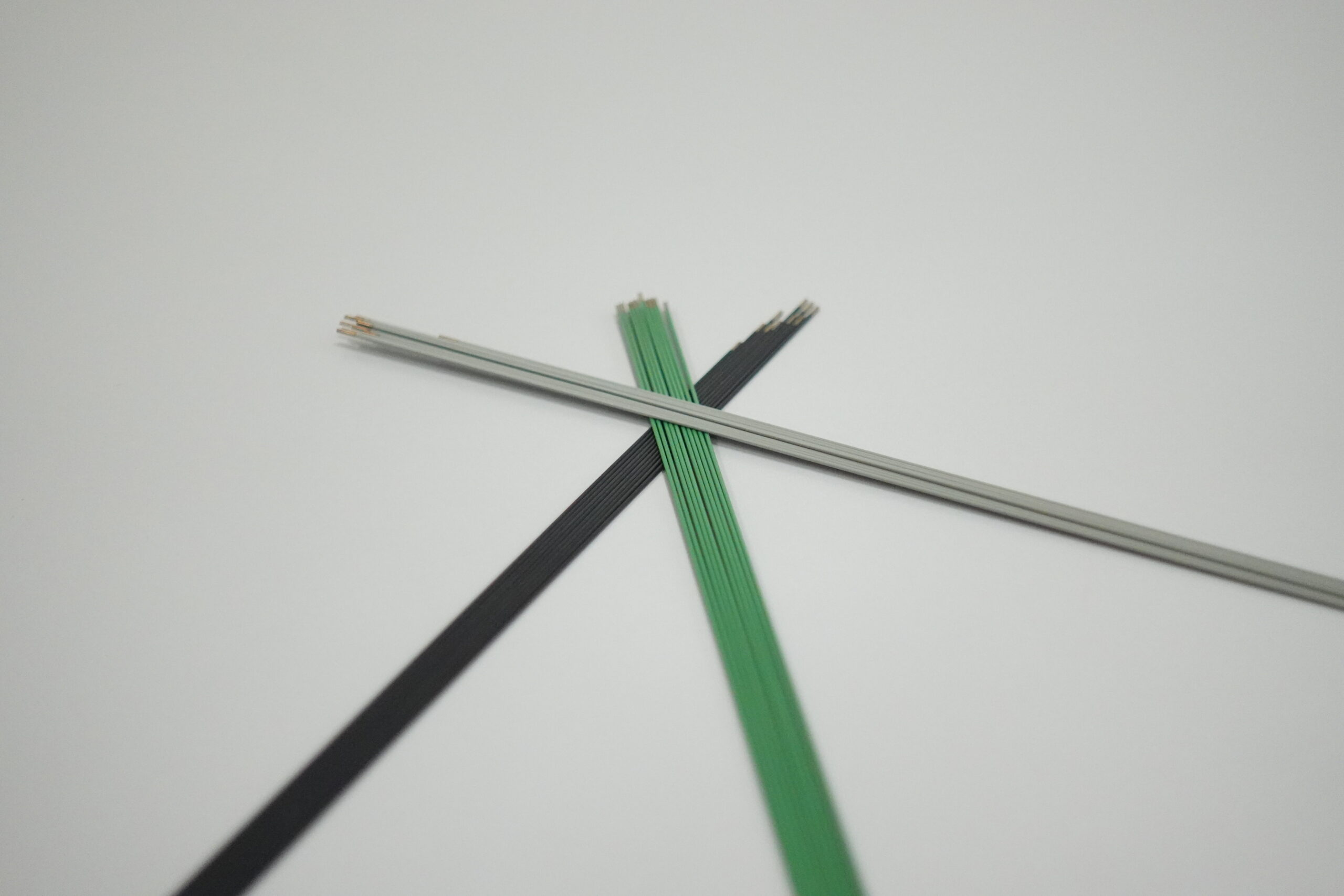

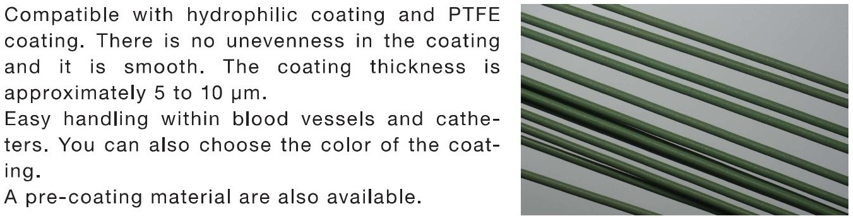

Possible to handle long coils and straight wires.

Coating can be applied to the wire before processing and to the coil after processing is performed.

Please refer to the technical page for compatible specs.

From 0.0762 (depending on the material and usage)