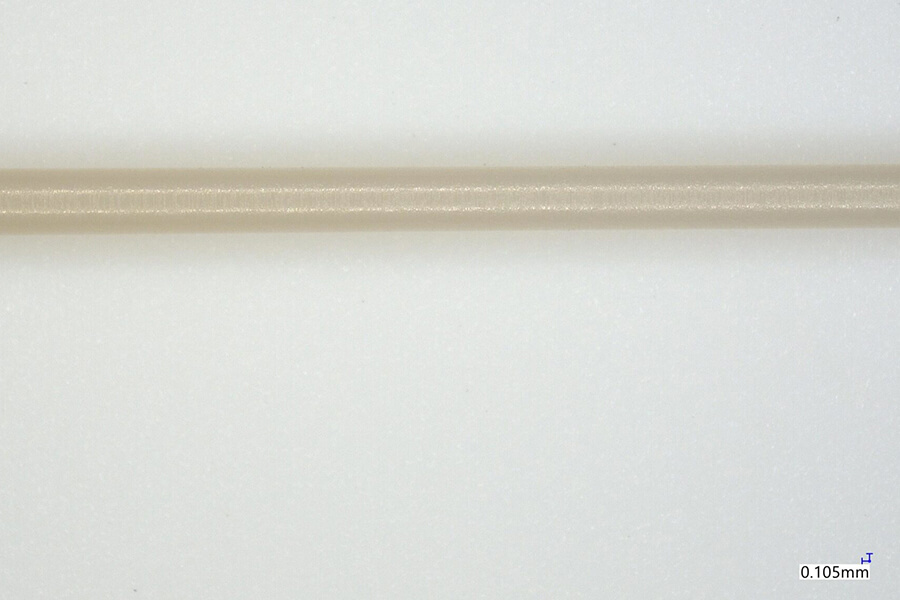

Classified as a super engineering plastic, it is used for products that require push-ability during insertion (mainly catheters, endoscopic instruments, analytical instruments, semiconductor manufacturing device, etc.).

With the world’s highest level of internal and external accuracy, it enables finer and thinner product designs.

Characteristics

- Finer・thinner( OD φ0.5~φ3.2mm thinnest 60㎛(0.060mm)

- World’s highest level of internal and external diameter accuracy (standard: ±30㎛, special specification: ±10㎛)

- High mechanical strength. Has excellent tensile strength, making it difficult to break and easy to insert.

- Provides excellent biocompatibility

- High heat resistance(continuous use temperature 260℃= highest level of plastic(equivalent to fluorine)

- High chemical resistance(not affected by most acids, alkalis and organic solvents = equivalent to fluorine

Main usage

- Endoscopic treatment tool inner tube

- Catheter inner tube

- Balloon catheter

- PTA catheter

- PEEK

Processing

- Straight pipe processing

- Bending

- Taper processing

- Various coating

- Bellows processing